First of all there was an idea, the idea of a new seperation of a stem clamping. Why not seperate the stem at the steerer tube?

Awesome new design. It works, looks nice, the weight was great. But when it comes to small series production I started to ask around for offers from the milling companies. One was 495 Euro per piece, just the milling. I was really frustrated. Can it be, that a stem made in germany would be that highpriced ?

For the customer this would be around 800 to 1000 Euro for a stem. I cancelled the project.

The “newmen” Michi Grätz came up with a one piece stem. My first thoughts where “oh, all the guys will ask, which handlebar will fit”. This always means lots of emails, lots of questions. But after a few weeks I was really keen on this idea.

Because it is – from technical view – the best solution to combine two tubes to each other. It is the lightest, most beautiful – and also cheapest solution. “Light, strong, cheap” – yes, take all of it! (some of you might think, cheap, hea? but for made in germany in small number of pieces, it is!)

A few weeks later the prototypes where done – a few month later the first series was done. Before this I had to make a dynamic test at EFBE-Prüftechnik. They told me “the stem has passed the E-Gravity programm” and asked me if I want to make additional onesided load tests….

“the stem also passed the additional tests, the small guy is really solid…”

But why is it that strong ?

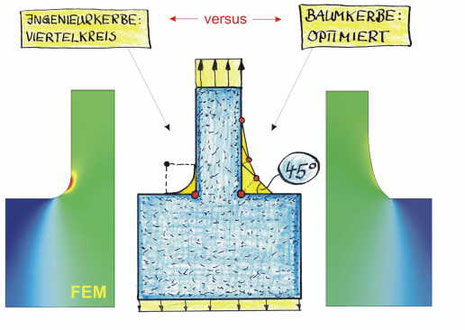

One of the answers is “Mr Mattheck”. He is a professor for trees. No joke. He developed the natural “chamfer”, which differs slighty from a “engineering chamfer”.